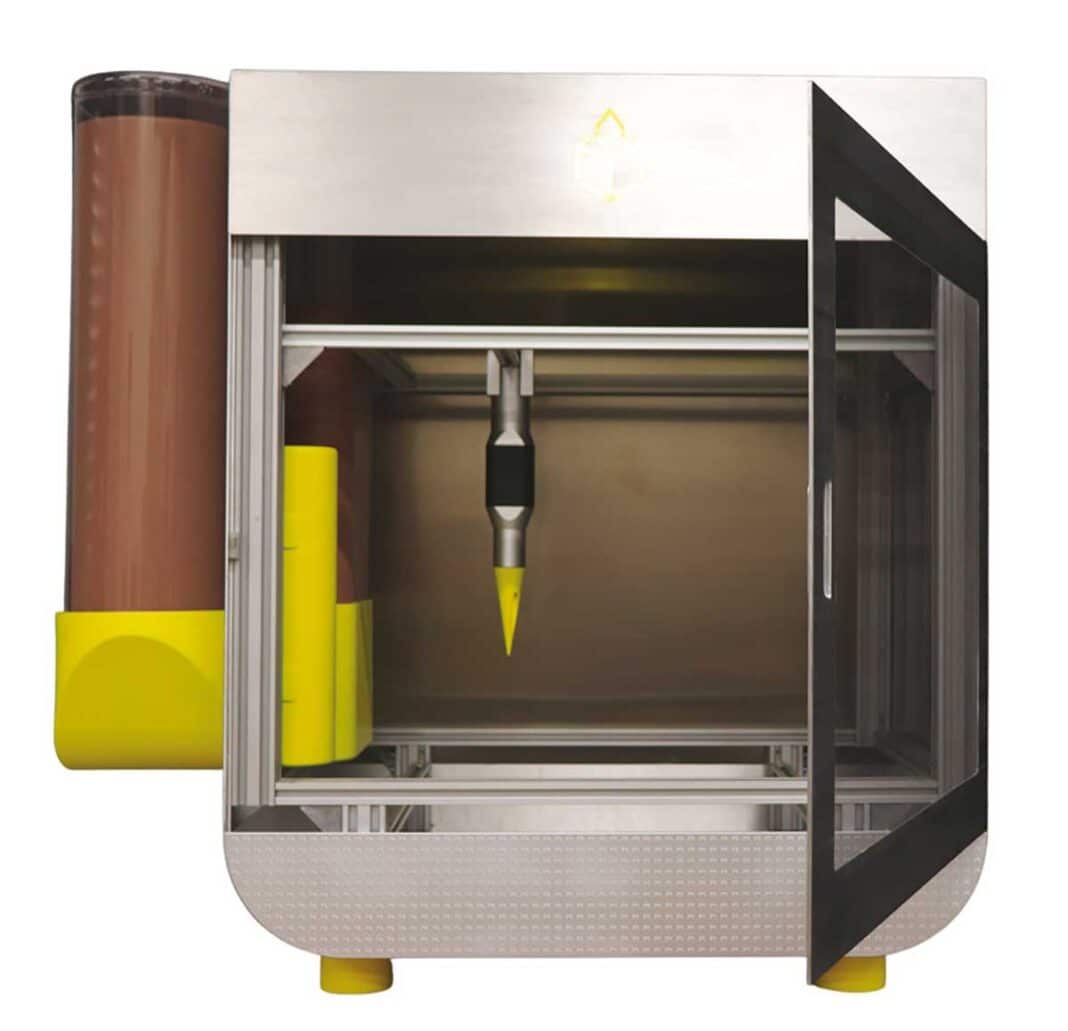

The start-up La Pâtisserie Numérique unveils Patiss3, the first culinary 3D printer capable of printing in volume without the addition of additives. This technology, which is aimed at pastry professionals, allows the development of free forms in record time. A culinary revolution made in France.

The 3D printing revolution reaches the world of pastry ! Digital Pastry is inspired by MIT technology which allows 3D food printing of pastries intended, For now, to a professional audience. Marine Coré-Baillais, knows founder, ex-DGA of Sculpteo, leader in 3D printing, and former member of Cédric Grolet's brigade at Le Meurice, innovates with this technology which frees creators from the enslavement of molds and gravity. This patented technology allows the development of free shapes down to the millimeter. Unlike so-called classic pastries which require hours of preparation and successive manipulations such as freezing, it divides time and manipulations by ten to offer unprecedented freedom to pastry chefs. This printer which is revolutionizing French and world gastronomy will be manufactured in France. Patiss3 was presented at the VivaTech show from June 15 to 18 at the Parc des Expositions. On this occasion, visitors were able to taste a 3D printed cake, fruit of a collaboration between La Pâtisserie Numérique and the Parisian design firm Possible Future. This dessert called Coral revisits an emblematic recipe of French pastry : the Concord. Chocolate mousse, meringue, cocoa shortcrust pastry and fruit confit were the main ingredients of this culinary innovation.

Patiss3 frees pastry chefs from gravity

The 3D printer is a connected machine that allows you to produce the structure of a pastry ready to be filled, while retaining the additive content of the original recipe thought by its author. Unlike existing 3D printing techniques using gel to solidify the structure as it is manufactured, Marine Coré-Baillais combined 3D technology with respect for taste by inventing a process inspired by MIT. The Patiss3 printer offers two powders which will literally support the structure during its manufacture : one is universal and has the least impact on the final taste of the pastry, whether salty or sweet, and the other is based on cocoa where work is carried out on the bitterness. The powder removal station allows you to recover the powder used during the printing phase. The powder is reusable up to seven times. Starting from a 3D file, it is possible to produce all possible and imaginable shapes, for example in biscuit, by controlling flavors and retaining the original taste of the recipe. The 3D printer is offered with additional modules : a powder removal station with recovery and an oven to optimize manufacturing times. Intended for pastries, restaurants and industrial biscuit factories, the Patiss3 printer includes a “marketplace” accessible via an application. This catalog of 3D models also contains recipes from recognized chefs. This app protects recipe creators, by contributing to the payment of royalties for each use of culinary creation found within the application, and allows professionals to offer signature dishes.

Digital Pastry had already revolutionized the culinary industry in 2020 with CakeWalk 3D, a device that converts a personal 3D printer into a culinary 3D printer, and its Slicer 3D print tracking software exclusively developed for food 3D printers. For Marine Coré-Baillais, “this culinary 3D printing technology puts within reach of all pastry chefs a production method allowing them to rethink shapes and flavors while freeing themselves from time constraints, gravity and handling. The entire creativity of an industry is turned upside down, for the pleasure of our taste buds. » With its new device, La Pâtisserie Numérique offers a hybrid business model that allows pastry customers to increase their profitability by nearly 26% by saving time on the manufacture of the most elaborate pastries, to reduce the costs of silicone or steel molds, but also to reuse the powder.