It is at the professional center of the Ravate group, and more precisely to its president and CEO, Abdoullah Rafate, that we owe the introduction to Reunion Island of this disruptive innovation in the world of construction : cement from the Vendée company Hoffmann Green Cement Technologies, first clinker-free, cold-produced cement in the world, to the carbon footprint divided by 3,5 compared to that of traditional cement. The innovation is also commercial since Ravate Pro is the first distributor of this product in 25 kg bags, that is to say intended for building craftsmen and individuals.

No more than their metropolitan counterparts, local professionals in the cement and construction sector are probably aware of this : the French company Hoffmann Green Cement Technologies begins to slowly shake, but surely, the metropolitan world of construction. HGCT’s Pro Cement emits up to 70% less CO2, according to its uses, compared to traditional cement. Stake? One ton of cement produces 881 kg of CO2. Cement represents 7% of CO2 emissions worldwide. Just in France, 18 million tonnes of cement are consumed per year. In application for new constructions in mainland France, environmental regulations (RE 2020) predicts a reduction in CO2 emissions from construction of around 35% in 2030. It is on this rate that most of the cement giants are working in search of, them too, a less carbon-intensive cement. Fifty percent of CO2 emissions from cement manufacturing come from carbon dioxide released by high-temperature firing. (1,450°C for sixteen hours) limestone, which is then ground and made into powder : clinker. The other 50% comes from the energy spent to produce this heat. The decarbonization of traditional cement necessarily involves reducing, as much as possible, the quantity of clinker. With its clinker-free cold-produced cement, Hoffmann Green Cement Technologies not only takes a step ahead, but calls into question the cement production process with a concept of vertical cement plant also unique in the world, in silo, which stages the different stages of the production process from top to bottom.

Innovation beyond the norm

The announcement of the distribution by the Ravate group of Pro Cement 52,5 H-UKR N, cement bas carbone from Hoffmann Green Cement Technologies, in 25 kg bags, gave rise, November 9th, at a conference at the Stella Matutina Museum. Order givers, project managers, architects, design offices, individual house construction companies, etc. : the professional building world listened to Julien Blanchard's explanations, chairman of the board and one of the two founders, with the chemist David Hoffmann, its general and scientific director, Hoffmann Green Cement Technologies. First of all, HGCT's low-carbon Pro Cement has obtained validation from the Scientific and Technical Building Center (CSTB) after five years of tests and a cost of ten million euros for the company Hoffmann Green Cement Technologies. The clinker is replaced, among others, by a formulation based on blast furnace slag (milkman), ashes from incinerated biomass, as well as gypsum extracted from plasterboard waste. This cement is white, and no longer gray. Its limited duration of use (eighteen months) is much superior to that of traditional cement (four months). It is used at equivalent dosage and without any modification to the concrete manufacturing process. Transport by boat from mainland France only increases its carbon footprint by 30 kg per tonne, which in no way diminishes its ecological superiority. Applicable indoors or outdoors, in reinforced or unreinforced concrete, without change in usual practices, this new low carbon cement has the same areas of use as traditional cement : concrete plant, construction site concrete, mortars, prefabrication.

The first projects

Reconciling business and social responsibility

HOFFMANN GREEN CEMENT TECHNOLOGIES IN FULL EXPANSION

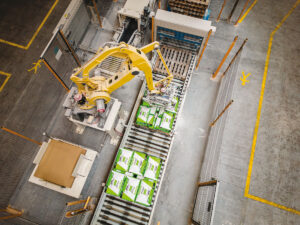

After a first factory producing 50,000 tonnes of cement per year in 2015, HGCT launched a second cement plant in 2022 with a capacity of 250,000 tonnes in Bournezeau in Vendée. A third location is planned in Dunkirk in 2026. Multiplying by 3,5 its sales volumes in one year, the company is today the sixth largest French cement manufacturer. This year it signed its first contract abroad in Saudi Arabia for the construction of three cement plants.. IPO in 2019, Hoffmann Green Cement raised 100 million euros for its development. On the scientific level, its objective is now to succeed in dividing by ten (instead of five currently) the carbon footprint of cement.