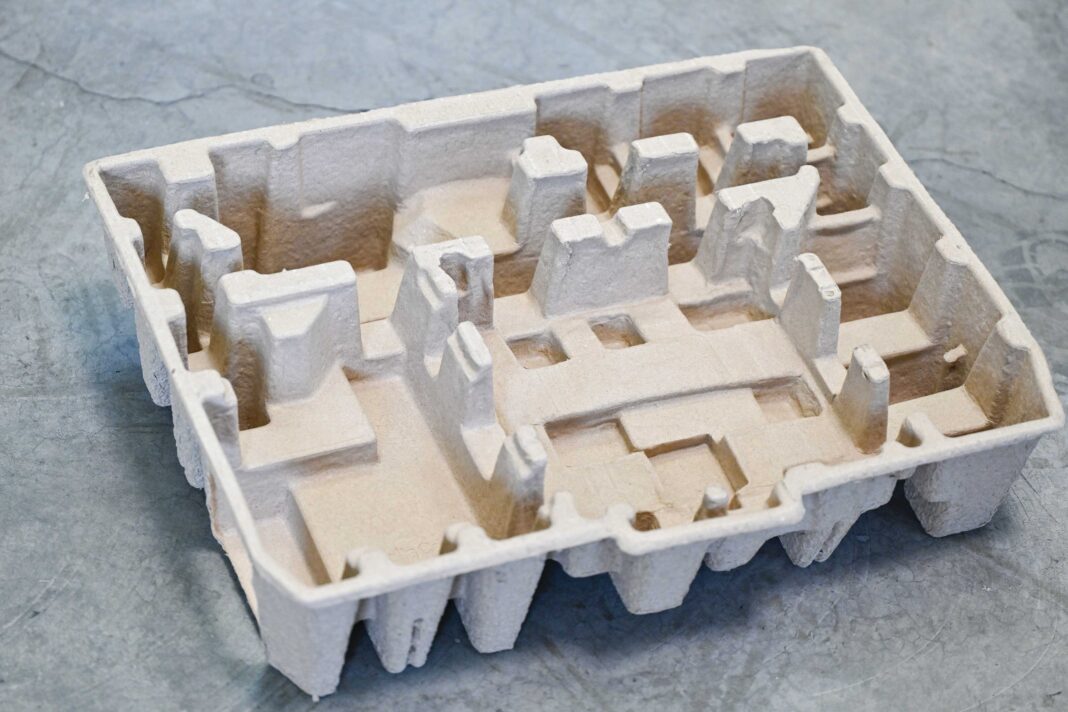

The future Reunion producer of cardboard pulp, whose factory will emerge from the ground in 2025 in the Port eco-park, already wishes to encourage and bring together industrial transformation projects. Preforms used for wedging products in packaging, flower pots, egg cartons, etc. : the applications promise to be multiple.

« We are open to all local projects that can use recycled cardboard pulp to make, by molding or blowing, finished products based on cellulosic fiber. There are a plethora of possible applications. Our dehydrated fiber will make it possible to produce all types of preformed supports for fragile products during transport.. Furthermore, these wedges, which are now thrown away as soon as the packaging is opened, can be recycled again. Same thing for egg cartons., the seed pots, disposable cardboard medical waste carriers. This pulp can also be used in the composition of thermal insulation. And there will be all the other uses we haven’t thought of… » The announcement is made by Marijke Payet, responsible for sustainable development at Pulp Eco, and by Olivier Morel, business consultant, Who, with Aimery Deleflie, director of Pulp Eco, have been advancing this pioneering project for five years : a cardboard recycling plant in Reunion, which will transform cardboard waste into dry or wet pulp. Which also encourages them to launch this call, there are only two metropolitan manufacturers of cellulose preforms, having heard of the project, have already contacted them...

Cardboard recycling in a small area

Pulp Eco is a waste trading company (carton, plastic, scrap) created in 2019, subsidiary of the Clinifutur Group*. The project for a local recycled cardboard factory was made public in 2021. In addition to the desire to promote a circular economy solution, it is motivated by the increasingly random nature of waste trading. Changes to European regulations on the cross-border transfer of waste, which tend to favor transfers to OECD countries, closing the borders of waste-importing countries, the cost and difficulties of exporting from Reunion Island, everything contributes to seeking solutions for autonomy in the recovery of waste. Metropolitan cardboard recycling plants are sized on a national scale. Pulp Eco innovates with a factory capable of exploiting a limited supply of cardboard waste. Fifty thousand tonnes of boxes enter Reunion every year. Barely 25 000 tonnes are then recovered to be re-exported and recycled. The rest ends up in landfill or disappears. Pulp Eco will need a minimum of 32 000 tons to run its machines continuously. The factory could also be supplied with cardboard waste from Mayotte.. It can recycle up to 40 000 tons of cardboard per year.

Expertise accessible to all

« The factory will close the loop in the Reunion cardboard paper industry without replacing what already exists. », would like to highlight Marijke Payet. There are many partners involved, starting with waste sorting and treatment operators and the packaging eco-organization Citeo. The major consumers of cardboard, such as mass distribution and manufacturers, are also listening. Cardboard pulp that will not be recycled on site will be exported for recycling elsewhere. The objective is to achieve the elimination of all landfilling of cardboard waste in the short term.. Pulp Eco a conscience que sa solution, once tested and validated, can be transposed to small islands and territories facing similar difficulties. Hence the other remarkable choice of the project : its refusal to be a source of profit. « All our know-how will be made freely available to any serious and reliable structure., wherever she comes from, who would like to implement it in the service of sustainable development », warn Marijke Payet and Olivier Morel.

* The Clinifutur group is pursuing another sustainable development activity with its subsidiary BA Eco, which produces urban and outdoor furniture from plastic materials and recycled milk cartons.