This name change demonstrates the desire of the industrialist based in Rivière-du-Mât (Bras-Panon) to make itself better known and to be clear and transparent about the conditions in which its products are manufactured : bottles and flasks, “zoiseau” bags, reusable bags, trash bags, agricultural mulch films,… and tomorrow also paper bags. A responsibility that the leader of the Reunion packaging market intends to assume with 75% of PDM. The two letters BP in the logo now read “Bourbon Packaging”. The new identity is available between this “parent” brand (Bourbon Packaging) and two “girl” brands : Bourbon Packaging Plastic and Bourbon Packaging Paper. BP is preparing to become the first and only local producer of paper bags for commerce. “The right packaging”, which becomes the signature of the company, and the appearance of a curved arrow covering BP symbolize the company's commitment to the circular economy which serves as a guiding principle for its development. Explanation by Muryel Leblanc, Managing Director of Bourbon Packaging : “Our new brand and our new logo are representative of our current way of producing : the search for the right quantity of material to produce the product adapted to a specific function. We are in an eco-design approach, circular economy, reduction of materials at source and recyclability, for all our products, while maintaining the quality standards that have always been ours. »

Paper bags : an import-substitution market

The manufacture of paper bags is an old project that receives investment assistance from France Relance, Last year, made it possible to realize. The project is also supported by a fashion brand that is a major consumer of paper packaging bags.. Bourbon Packaging rehabilitated an old premises which served as a warehouse to install this new production workshop ready to come into operation. In order to register the event in its territory and within these walls, BP called on graffiti artist Yvren to decorate the interior of the workshop with a fresco and highlight Reunion’s diversity through portraits of women. Two jobs are created, bringing the company's workforce to nearly 50 people. “It’s a project we’ve been thinking about for a long time.. Paper bags are a 100% imported market. There is a demand for this type of product. We offer a local paper packaging solution available throughout the year and within reasonable deadlines.. Unlike imports which, to anticipate delivery times of several months, force businesses to order, buy and store bags at once for the whole year. We are the short circuit answer. » Bourbon Packaging Papier offers a range of several sizes of paper bags with handles, and already another development is planned : paper bag without handle, American style, which would open up the market for other uses, like the packaging of fresh products…

Garbage bags made from 70% recycled plastic

Recycling plastics is another objective of Bourbon Packaging. The increase from 30% to 70% of the rate of regenerated plastic in the composition of its garbage bags is another testimony to the company's efforts.. At his request, Leclerc distributed a “preview” of a reserved range of pei trash bags – with and without sliding ties – displaying 70% recycled plastic. These bags will soon be available everywhere. This progress is made possible by the increase in raw materials recycled by the company which has its own recycling unit., the only one existing in Reunion for over 20 years. The modernization of this workshop has made it possible to increase the volumes processed. 400 tonnes of plastic waste are recycled annually by BP. Waste from several sources : manufacturing scraps within the company and among BP customers, flows collected by associations with which the company has entered into partnerships (Antzip, AC2V, Next Compost), to capture deposits compatible with its production process. The recycling unit could do a lot more : it operates at a third of its capacity. BP has given itself the means to achieve its ambition in this area. Also don't forget that the famous "zoiseau" shopping bags sold in supermarkets are another major outlet for recycled plastic at BP : they include more than 30% locally recycled material.

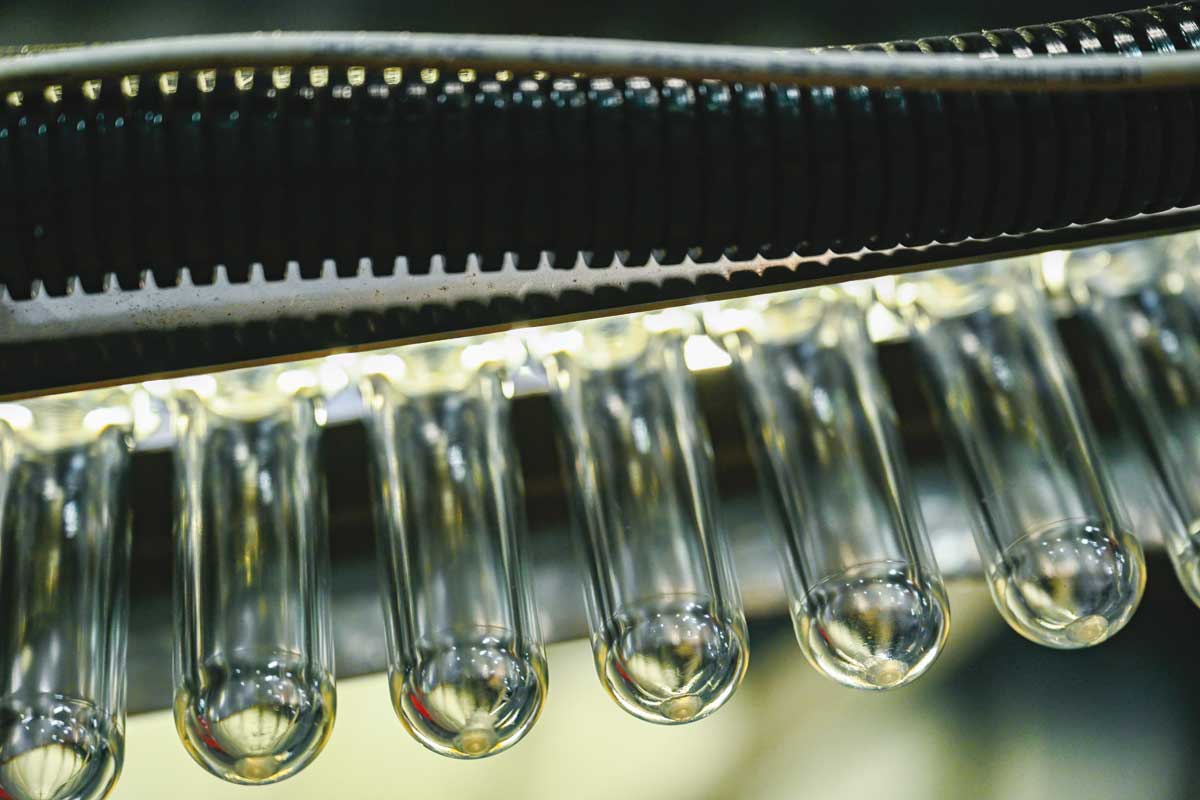

Flaconnage : from PVC to PET

The new corporate identity that appears today was built in stages. One of the most significant on an industrial level was undoubtedly, in 2021, the replacement of PVC material by PET material in the manufacture of bottles and flasks. “A huge change for us. The transition to PET leads us to review the entire organization and layout of the company”, then underlined in Leader Réunion Muryel Leblanc and Jean-Claude Leblanc, president of Bourbon Packaging. PET bottles are made from imported preforms. Less imported raw material, a greater breadth of range to offer to customers of small series in which the company is a specialist, and the recyclability of PET : these are the advantages of this mutation.

A bioplastic from Bourbon Packaging

In terms of technical advances made by the company, we must remember the manufacture of an agricultural mulch film based on starch. Designing a biodegradable plastic in tropical conditions : the BIODOM project initiated by the Committee for Plastics in Agriculture (CPA, a national organization) set this goal in 2018. This bioplastic mulch was studied in collaboration with the Chamber of Agriculture, l’Armeflhor, (Reunion Island Association for the Modernization of the Fruit Economy, vegetable and horticultural) and the Qualitropic competitiveness cluster. Mulching is used to protect market garden plants during the germination period.. A biodegradable film avoids having to pick it up at the end of its use. A practical advantage. But it was a question of designing a product whose biodegradability – that is to say its duration of existence – was predictable as far as possible depending on the altitude and climatic conditions.. After five years of development, the product saw the light of day in 2021 in the Bras-Panon factory.